We have a steel billet making plant in Rusayl Industrial Estate, Muscat (Oman) and it has been operating from September 2014 onward. The plant capacity is 200,000 MT per annum. The secondary steel making technology is based upon EAF-LRF and BCM route.

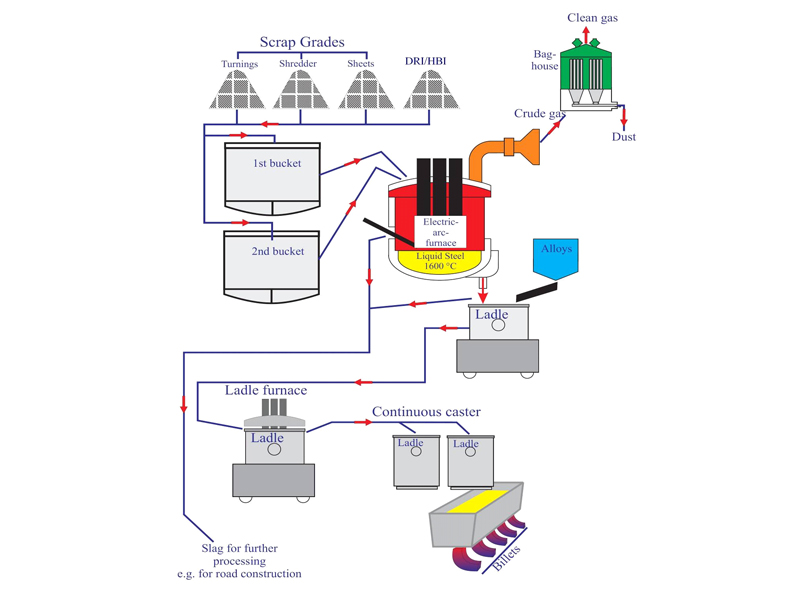

In manufacturing the steel billet through electric arc furnace following main equipment are used.

- Scrap Shear machine.

- Electric Arc furnace.

- Ladle refining furnace.

- Continuous Casting machine.

In the very first stage the incoming scrap, local/import is inspected for its quality in terms of chemistry and size. Most of the cases the local scrap collectors are not well-equipped to supply the process scrap. So it becomes essential to process the incoming oversized and light scrap through Sheer machine to increase its bulk density which helps to reduce the number of charges resulting better power utilization and reduction of power losses.

In second stage the required size of scrap is fed to Electric arc furnace through EOT cranes and its melting is based on high power input rate with Low secondary voltage and high current (KA).

The combination of Oxygen along with lime and coke is used for:

- Oxygen as an additional source of energy (Chemical) for reducing the heat timing and de-phosphorization.

- Formation of slag coating over refractory lining for its protection.

- For maintaining the foamy slag practice for reducing power consumption and refractory wear. Just before tapping, it is confirmed for chemistry and temperature for further processing the heat at LRF.

- Improving the power quality by providing SVC.

- Fume extraction system is provided to maintain the dust fumes and gas level (Co2, Co, So2) in the plant as per norms suggested by ministry of environment.

In the third stage after receiving the liquid steel from EAF with proper chemistry and temperature, further processing is done at LRF for correcting the chemistry by addition of ferroalloys, coke and calcined Lime as per grade and increase of temperature by use of electrical power. Argon gas is used for purging purpose from the bottom of ladle for homogenization of Ferroalloys and temperature throughout the liquid steel.

In the fourth stage the heat is transferred to the turrete by the help of EOT crane. In this process the liquid steel passes through an intermediate vessel (Tundish) to copper mould tube surrounded by a water cooled jacket for transforming the liquid steel into solidified steel billets with different cross section [100,120,130,150mm2] and an auto Gega cutter is provided for cutting the solidified steel billets into required lengths. These billets are transferred to Intermediate cooling bed for straightening and lowering of temperature. For final storage of billets are transferred by the help of a magnet crane.

Apart from the technology and process used for the steel making, two major aspects are considered:

The schematic diagram of above process is as below: